In the world of heavy industries and construction, where precision and reliability define success, DOMANA stands out as an emerging global brand manufacturing concrete cutting equipment while delivering integrated smart solutions powered by the Internet of Things (IoT). We do not simply offer tools; we create an advanced ecosystem that combines precision mechanical engineering with artificial intelligence and cloud-based control elevating efficiency, safety, and profitability to entirely new levels.

Our ambition knows no limits. We began with a clear vision to redefine the manufacturing, testing, and maintenance of concrete cutting equipment (Wall Saw), and we are steadily advancing toward our greater goal: to become leaders in the production of drilling, mining, and other industrial equipment competing with major global brands through purely Egyptian thinking, European standards, and relentless innovation.

Most traditional methods for testing concrete cutting equipment, such as Wall Saws, rely on visual and superficial evaluations. These approaches overlook the most critical factor: simulating real operating conditions. Ignoring essential elements such as the cutting disc’s weight during testing represents a fundamental flaw that can lead to several serious issues.

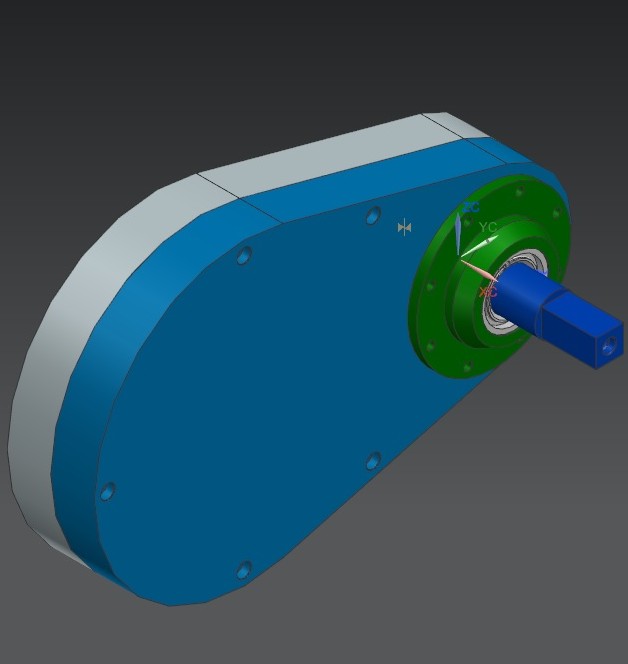

We have developed a unified testing system for concrete cutting equipment and power units across all models in a single device. It is more than a conventional inspection station; it is a fully integrated smart diagnostic center. The system precisely recreates harsh operating conditions to mirror real-world usage. Traditional testing limitations often result in: Misleading outcomes that fail to reflect actual performance under full load at job sites. Hidden faults that are difficult to detect early, such as gear wear, bearing damage, or safety clutch degradation leading to failures discovered too late. High and unpredictable costs caused by sudden on-site breakdowns, resulting in downtime, emergency maintenance expenses, and reduced confidence in equipment reliability. These shortcomings were the primary driver behind DOMANA’s radical shift in testing methodology from conventional reactive testing to proactive, predictive testing. This approach enables DOMANA to verify product quality with greater accuracy while offering customers a sufficient and reliable warranty period.

The testing goes beyond running the engine without a load. Dynamic load brakes gradually and systematically increase pressure on the motor, while the cutting disc’s weight is incorporated as a key factor in the test equation. This is what sets our system apart from traditional testing methods used by other brands, forcing the equipment to reveal hidden faults that often go unnoticed.

Thanks to precise load control and continuous performance monitoring, the system can detect issues before they escalate, such as: Early gear wear before causing complete failure. Damage to motor bearings and the rotor (roller bearings). Accurate measurement of safety clutch wear in percentage terms, helping determine the optimal replacement time.

We transform raw data into strategic insights delivered instantly through the DOMANA smart app, keeping you fully informed about your equipment’s condition at all times. Real-World Example: If a wall saw motor typically operates at an average load of 3 amps, and the data reveals a gradual, continuous increase to 4.5 amps, the DOMANA app immediately activates predictive indicators. The system warns of potential internal winding deterioration or bearing issues. This insight allows you to schedule timely maintenance, preventing complete equipment failure or motor burnout events that could cost thousands of dollars and delay your project by days.

Detailed monitoring of operating hours, downtime, and all key performance indicators reflecting operational efficiency. Precise Fault Diagnosis If any malfunction occurs, the system doesn’t just send a general alert; it provides a detailed report showing the exact fault percentage and the affected component—for example, 65% wear on the safety clutch or a 40% abnormal increase in motor load.

Advanced energy efficiency and consumption monitoring, treating them as key indicators of motor health. The ultimate goal is to help you make informed maintenance decisions, reduce unexpected failures, and turn maintenance from an unplanned burden into a carefully planned and cost-effective process.

The device is designed as a practical, all-in-one solution, allowing a single testing unit to inspect a wide range of models and equipment in a short time. With support for torques up to 800 Nm, it helps reduce total ownership costs while boosting workshop efficiency and productivity.

We have completely transformed the concept of maintenance, shifting from a reactive repair approach to a smarter method that prevents faults up to two weeks in advance—this is the core of DOMANA’s predictive maintenance principle.

Instead of predicting a fault just 24 hours in advance, we’ve expanded the system’s predictive capability to 15 days before the actual failure, providing ample time for informed decision-making.

The app monitors any gradual decline in motor efficiency, tracking its daily condition and impact on lifespan without relying on sudden failures.

When any component, such as the motor, approaches a critical performance level, the system sends an alert to the user, providing a 48-hour window to plan and take action—allowing issues to be addressed weeks before they escalate.

A permanent digital record is kept for each piece of equipment, including every test, reading, and maintenance action, all documented by its model number, creating a comprehensive database that supports governance and future trend analysis.

Years of Experience

Done total project

working on project

Qualified Workers

Because all our software is developed entirely in-house, without reliance on external parties, we deliver a fully integrated ecosystem designed with a future-focused vision—making your operations smarter, smoother, and more adaptable. Remote Operation & Testing: Authorized agents and operators can easily start, stop, and manage testing devices and equipment, whether inside workshops or off-site. The system also enables secure remote control of concrete cutting equipment deployed at project locations through protected IoT applications. Unified Operating Platform: Monitor operations, receive reports, and manage user permissions based on roles—all through the centralized DOMANA app, built for practicality and ease of use. Security & Technological Sovereignty: All software systems—from device operating frameworks to mobile applications and cloud platforms—are fully developed by DOMANA. This ensures maximum cybersecurity, seamless system integration, direct technical support, and complete technological independence.

Lorem ipsum dolor sit amet, consettur adipiscing elit, sed do eiusmod tempor incididunt ut lab

Lorem ipsum dolor sit amet, consettur adipiscing elit, sed do eiusmod tempor incididunt ut lab

Lorem ipsum dolor sit amet, consettur adipiscing elit, sed do eiusmod tempor incididunt ut lab

Lorem ipsum dolor sit amet, consettur adipiscing elit, sed do eiusmod tempor incididunt ut lab

15,400 EGP

Versatile and powerful SDS Max (TE-Y) rotary hammer for concrete drilling and chiseling, with Active Vibration Reduction (AVR)Weight according EPTA-Procedure 01/2003 without battery: 15 lbSingle impact energy: 5.8 ft-lbsRated current: 13 ACustomers also searched for concrete drill, rotary hammer, hammer drill, rotary hammer drill or SDS MAX Rotary Hammer.

Product DetailsAt Hilti we understand it’s not always easy to know exactly what product, service or software may be the best to serve your needs.

Why DOMANA is Your Strategic Partner for the Future

At DOMANA, we don’t simply sell or manufacture products we deliver a complete digital transformation. We provide confidence, full operational control, and stronger long-term profitability.

1-The first to fully integrate Internet of Things (IoT) technologies into smart concrete cutting equipment.

2-A fundamental solution to the cutting disc weight challenge during testing and the hidden faults often overlooked by competitors.

3-Predictive maintenance minimizes costly downtime, while multi-model testing in a single device reduces unnecessary capital investments.

4-100% proprietary software ensuring continuous updates, rapid support, and enhanced security.

5-Partnering with DOMANA is a direct investment in the future of the digital industrial equipment sector.

DOMANA is more than a startup it is a promise of a smarter, safer, and more efficient industrial future. Join us as we redefine the rules of the heavy equipment industry, where ambition is limitless and technological potential never ends.

DOMANA… the intelligence that cuts concrete and builds the future.

Comprehensive Future Vision: Precision Reverse Engineering with Modern Innovation

What we deliver today is only the first step in a carefully planned journey. At DOMANA, our vision extends far beyond the present. We are building a new generation of connected smart industrial ecosystems where innovation is foundational and integration is the standard.

Expanding the Product Scope

DOMANA’s ambitions go beyond concrete cutting equipment. We are strategically advancing toward the manufacturing of drilling equipment, mining machinery, and a broader range of heavy industrial systems integrating DOMANA’s connected intelligence and full digitalization into every product.

Integrated Project Management Ecosystem

We envision a future where major contractors manage entire equipment fleets through a single centralized platform. This ecosystem will enable location tracking, performance monitoring, technical condition assessment, maintenance scheduling, and precise cost analysis for each machine across every project.

The Data Economy

The data we collect will not remain as raw numbers. It will evolve into collective intelligence that drives the development of next-generation equipment and provides decision-makers with actionable, industry-wide insights.

Global Partnerships

We aim for DOMANA’s platforms and technologies to become a proposed technical standard in major infrastructure projects through strategic partnerships with leading construction and engineering firms worldwide.

Comprehensive Technical Philosophy

DOMANA represents more than technological advancement it reflects a shift in industrial thinking. A transition from “manufacture and rely on warranty” to a deeper model focused on guaranteeing performance throughout the equipment lifecycle. This is achieved through an integrated system built on:

1-High-precision physical simulation extending beyond traditional mathematical models to dynamic thermal and mechanical representations of real operating conditions.

2-Advanced diagnostic artificial intelligence capable of continuous learning and predicting failures before they occur not merely reacting to breakdowns.

3-Full partner empowerment by providing access to the same manufacturing, testing, and diagnostic capabilitiestransforming partners into certified service and diagnostic centers.

4-The creation of parallel digital assets for every physical machine, enhancing value, reliability, and future resale potential through verified performance histories.

With this comprehensive vision, customer confidence becomes measurable rather than conceptual grounded in data, powered by advanced technologies, and aligned with a new industrial standard where quality is no longer an advantage, but the baseline.

Content AS HTML